Dedusting systems: Baghouse Filters - Cyclones & Multicyclones - Wet Scrubbers

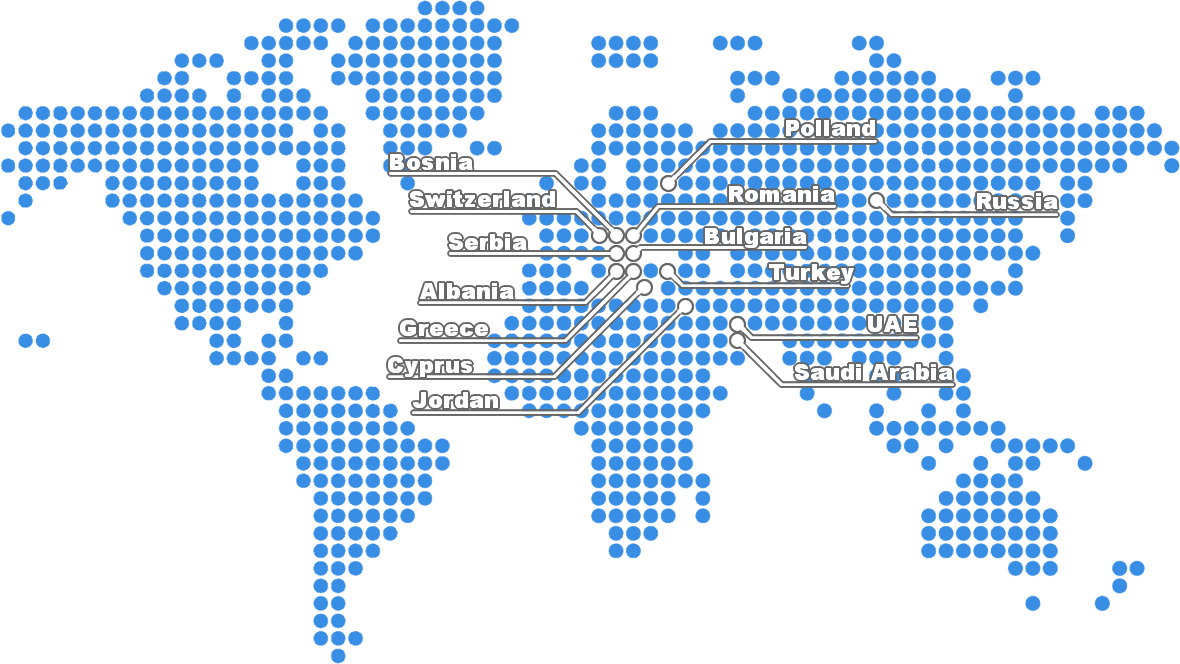

P&M Engineering designs, manufactures, and installs dust collection systems for particle removal worldwide for over 20 years.

Driven by our commitment to industrial air cleaning and environmental protection, we offer high-performance solutions that ensure compliance with international emission standards.

What is Dedusting?

Dedusting (dust collection) is the process of removing suspended particles such as dust, ash, metals, and other solid pollutants from an air stream using appropriate equipment.

The main goals are to protect the environment, improve indoor and outdoor air quality, and prevent damage or contamination of equipment and final products.

P&M Engineering can provide a wide range of customized solutions for your facility’s dedusting needs, designed to fit your available space and operating conditions.

Our Solutions

- Baghouse Filters

Ideal for fine dust (<10 μm) with clean air outlet concentrations of PM10 < 5 mg/m³.

In special applications, outlet concentrations below 0.5 mg/m³ can be achieved. - Cyclones and Multicyclones

Suitable for pre-filtration or large particles, offering low operating costs.

Often installed upstream of a bag filter to reduce dust load. - Wet Scrubbers

Combined removal of dust and gaseous pollutants in a single unit.

Options include Venturi Scrubbers and Mechanical Scrubbers.

Advantages & Technical Features

- Dust retention efficiency up to 99.9%, even for particles smaller than 1 μm.

- Customized design based on air flow, dust characteristics, and available space (from 100 m³/h to over 100.000 m³/h).

- Manufactured in Greece, according to strict European regulations.

- Automatic cleaning system (air pulse or mechanical shaking) for reduced maintenance and consistent performance.

- Low pressure drop and high energy efficiency, minimizing operating costs.

- Integrated sensors and automation for continuous monitoring of operation, pressure, and air cleanliness.

- Turnkey solutions — from air ducting and ventilation systems to complete air cleaning installations.

Applications

Our dedusting systems are widely used in:

- Waste combustion and incineration plants

- Cement and lime industries

- Metallurgical and steel plants

- Chemical and pharmaceutical production

- Wood, food, and feed processing

- Silos, conveying, and material storage units

Contact Us

Let our engineering team evaluate your facility’s needs and propose the most efficient dedusting solution. We are at your service for study, technical offers, and full project support.