Venturi scrubbers & mechanical scrubbers

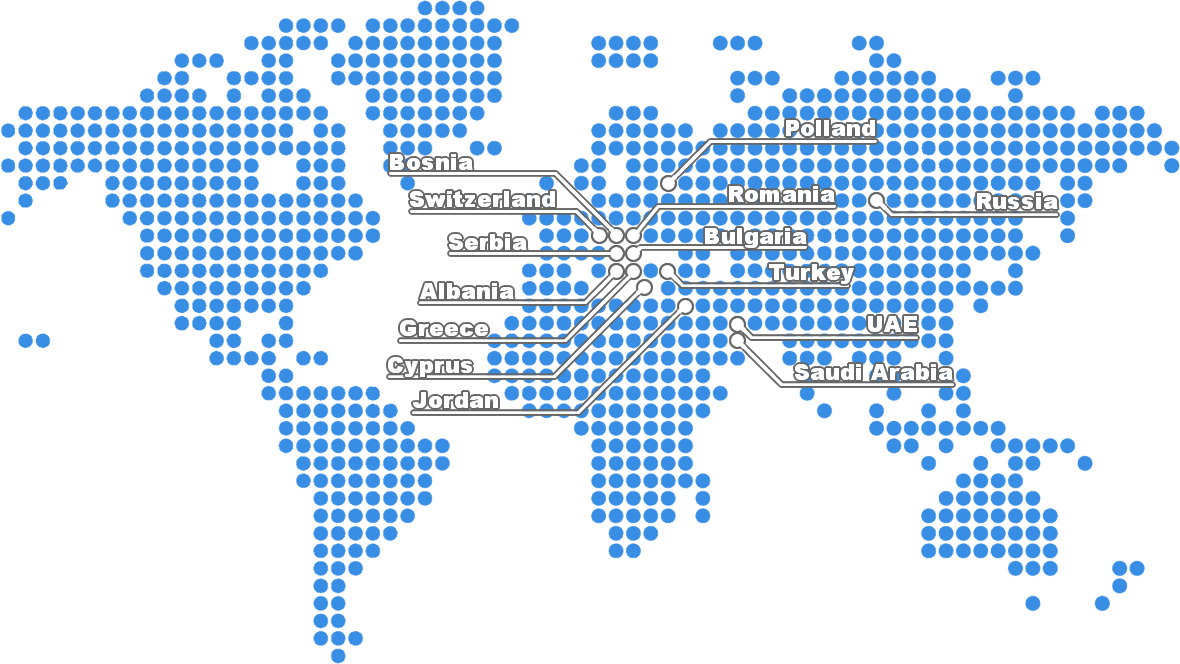

P&M Engineering, with more than twenty years of experience in air pollutant control, can provide Venturi scrubber systems and mechanical scrubbers for the dust removal needs of your facility.

Venturi Scrubbers

The basic operating principle of Venturi scrubbers is based on accelerating the gas stream through a converging throat while water or a suitable solution is sprayed into it. This increases turbulence, which in turn enhances contact between particles and the sprayed liquid.

Proper calculation of velocities inside the unit (60–150 m/s in the throat), the throat length, and spray droplet diameter are critical parameters determining the system’s efficiency.

Venturi scrubbers are suitable for controlling particles over a wide size range and achieve very high removal efficiencies for particles >1 μm. They also offer the advantage of simultaneously suppressing other pollutants in the air stream (e.g., aerosols, oils).

Main Advantages

- High efficiency even for fine particles

- Gas pollutant absorption and dust collection in a single unit

- Capable of handling flammable or explosive dusts with low risk

- Cooling of hot gases

Mechanical Scrubbers

Mechanical scrubbers are an additional method of dust removal using water, applied in cases where spray systems are not appropriate.

Air enters a vessel equipped with appropriately positioned blades and curves, guiding the stream into contact with the water inside the vessel.

Particle collection occurs at the gas–liquid interface and is less efficient compared to spray systems.

The main advantage of this method is the absence of pumps or other moving parts, resulting in very low maintenance requirements.