Industrial filters - Bag filters

Our company designs and manufactures all types of self-cleaning industrial filters, including:

- Rectangular or cylindrical bag filters

- Cartridge filters

- Pocket-type filter elements

We can customize the final dimensions to match each client’s spatial and operational requirements.

Self-cleaning bag filters are the most widely used dust collection solution in modern industry.

Reliable and cost-effective operation, as well as compliance with emission limits, depend on careful design for each application.

The most common type — can be built in any size or filtration area.

Filter bags are available in a wide range of technical fabrics depending on the dust type and process conditions (temperature, humidity, etc.).

Usually built for smaller filtration areas and lower air volumes.

Their round shape prevents dust buildup in corners, making them suitable for sticky or poorly flowing dusts.

They also withstand higher negative pressures without special reinforcements, making them ideal for high-vacuum or ATEX-rated installations.

These filters provide large filtration areas within compact housings, ideal where space is limited.

However, due to the pleated structure of the cartridges, dust removal can be more difficult, often requiring low air-to-cloth ratios.

Pocket-type filters are suitable for low-height spaces, as the filter elements can be replaced horizontally from the front side. They require a larger filtration area for a given air flow compared to round bag filters, which must be considered during design.

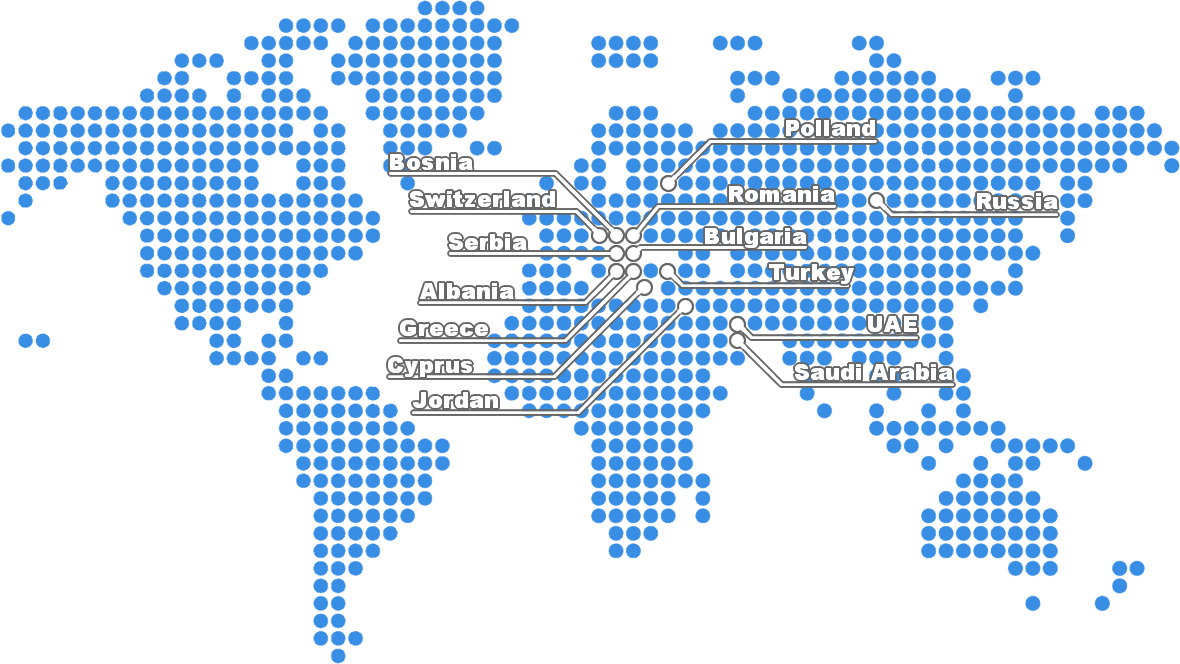

With our expertise and extensive client base, P&M Engineering can offer the most suitable industrial filter type for your installation.

Functional description of industrial self-cleaning bag filters

How Self-Cleaning Bag Filters Work

Dust-laden air passes through the filter elements (bags, cartridges, or pockets), which trap particles while allowing clean air to pass through.

- Dust accumulates on the outer surface of the filter media.

- Clean air exits through the outlet.

- At regular intervals, compressed air pulses are released inside the filter elements via special nozzles.

- The resulting shock dislodges dust from the surface, which falls into the hopper and is removed via a screw conveyor, rotary valve, or other system.

A differential pressure gauge monitors filter performance by measuring pressure drop between the clean and dirty sides, indicating when maintenance or bag replacement is needed.

Contact Us

Contact our technical team to evaluate your plant’s needs and suggest the optimal industrial filter solution. We provide full design, technical proposals, and support throughout the project lifecycle.